PRODUCT

Ultrasonic Rail Flaw Detector

> PRODUCT > Inspection Equipment

> PRODUCT > Inspection Equipment

> Ultrasonic Rail Flaw Detector

- Ultrasonic Rail Flaw

Detector - Manual Rail Flaw

Detection Device - Rail Profile

Measuring Device - Motion Logger

EKANG Solution

Ultrasonic Rail Flaw Detector

OVERVIEW

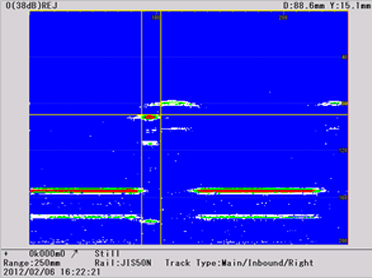

It is an equipment to detect cracks and defects in head, web, and bottom of rails. And it has more than 5 channels.

CHARACTERISTIC

- Use the dedicated program to display the results of inspection.

- With bottom display function as the standard specification, it is possible to detect the bottom corrosion caused by the whole ceremony and quantitatively evaluate the corrosion amount of the corrosion spot.

- Supply calibration rail for sensitivity.

SPECIFICATION

| Operating Method | Ultrasonic pulse reflection method |

|---|---|

| Display | A scope and B scope Possible to 4 and 6 screen split display per each probe |

| Applied Probe | 5HMz vertical probe / 2HMz angled probe 0° vertical : shelling , Horizontal cracking, bottom corrosion 45° angled : Transverse crack, bolt hole 70° angled : Rail Head Transverse crack |

| Operating Temperature Range | 0~+45℃ |

| Input / output terminal | USB terminal |

| Power | lead-acid battery(12V, 12AH) |

| Continuous operation time | Approximately 5 hours |

| Dimension | W600*D450*H920 mm (Main body) |

| Weight | Main body : Approx. 18kg (except battery and couplant) Battery : Approx. 4.5KG Storage Case : Approx. 15KG |